As the construction industry continues to grow and evolve, the importance of sustainability cannot be overstated. One key factor in achieving sustainable building practices is precast panel detailing. Precast detailing involves manufacturing building components offsite and transporting them to the construction site for assembly. This method has gained popularity in recent years due to its cost and time efficiency, but it also has significant benefits for sustainability. This blog post explores how precast detailing can contribute to sustainable building practices and why it is becoming an increasingly important factor in the construction industry.

Importance of Sustainability in the Construction Industry

Sustainability has become a key focus in the construction industry due to its environmental, economic, and social benefits. Sustainable building practices aim to minimize the negative environmental impact while reducing energy consumption and operating costs. Additionally, sustainable practices promote social responsibility by creating healthy and safe living environments for building occupants.

Precast panel detailing plays a crucial role in achieving sustainable building practices. By manufacturing building components offsite, precast detailing reduces waste and energy consumption and lowers the carbon footprint of the construction process. Furthermore, precast detailing can utilize eco-friendly materials, such as recycled steel and locally sourced aggregates, which can also contribute to sustainability efforts.

Role of Precast Detailing in Achieving Sustainability

The advantages of precast detailing for achieving sustainability are numerous. The process reduces waste and environmental impact by minimizing the amount of material needed on-site. Additionally, precast detailing allows for greater control over the manufacturing process, leading to higher-quality components and fewer defects.

Compared to traditional construction methods, precast detailing also has a lower carbon footprint. The offsite manufacturing process reduces transportation emissions and energy usage on-site. Additionally, precast components can be designed to maximize energy efficiency and minimize thermal bridging, further contributing to sustainability efforts.

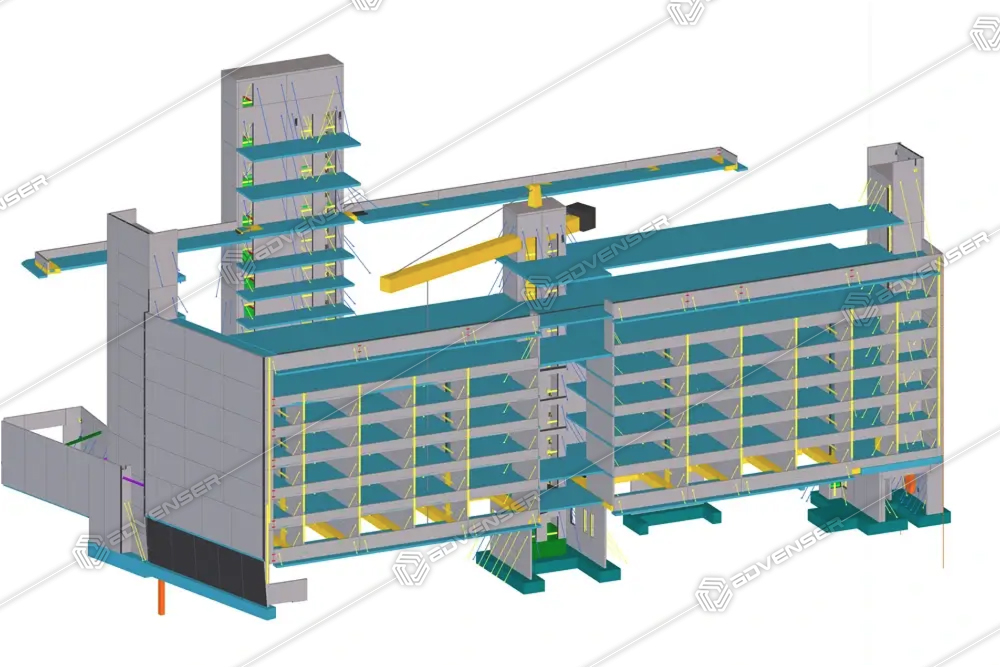

One key aspect of achieving sustainability with precast detailing is the use of Building Information Modeling (BIM) technology. BIM technology allows the creation of 3D digital models that contain detailed information about the project, including building materials, structural systems, mechanical and electrical systems, and more. This information can be used to simulate the construction process and identify potential issues before they occur, improving efficiency and reducing waste.

In precast detailing, Building Information Modeling (BIM) services plays a critical role in achieving sustainability. With BIM technology, precast concrete panels can be modeled and analyzed in detail, allowing for more precise fabrication and reducing the amount of material waste. Furthermore, BIM services can help optimize the design and placement of precast panels, reducing the need for additional support and improving the energy efficiency of the building. By simulating various scenarios, BIM can help identify potential problems and recommend solutions that contribute to sustainability.

Benefits of Precast Detailing for Sustainability

- Reduced Material Usage: Precast detailing involves creating building components offsite in a controlled environment, which allows for more efficient use of materials. This means that less material is wasted during the construction process, reducing the impact on the environment.

- Reduced Waste and Emissions: By creating building components offsite, precast detailing also reduces the amount of waste generated on the construction site. This can lead to a significant reduction in emissions and a more sustainable building process.

- Energy Efficiency: Precast detailing can also contribute to energy efficiency in buildings. The components can be designed to maximize thermal performance, reducing the amount of energy required for heating and cooling.

- Durability and Longevity: Precast components are typically more durable than traditional building materials, which means that they require less maintenance and replacement over time. This can lead to a more sustainable building overall.

Examples of Sustainable Building Projects with Precast Detailing

There are numerous examples of successful sustainable building projects that have utilized precast detailing.

One Angel Square, Manchester, UK: This building is considered one of the most sustainable office buildings in the world and has won numerous awards for its sustainable design. Precast concrete was used extensively in the construction of the building, resulting in a significant reduction in carbon emissions during the construction phase.

Hudson Yards, New York City, USA: Hudson Yards is the largest private real estate development in the US and incorporates a range of sustainable design features, including the use of precast concrete. The precast concrete elements were manufactured offsite, resulting in a reduction in waste and noise pollution during construction.

The Bullitt Center, Seattle, USA: The Bullitt Center is a six-story office building that was designed to be one of the greenest commercial buildings in the world. Precast concrete was used in the construction of the building, which helped to achieve a high level of energy efficiency and reduced the building's overall carbon footprint.

Future of Precast Detailing and Sustainability

As the construction industry continues to embrace sustainability as a core principle, the future of precast detailing looks bright. Experts predict that precast detailing will continue to play an important role in sustainable building practices for years to come.

One of the most significant trends in the future of precast detailing is the integration of smart technology. As technology continues to evolve, precast detailing companies are finding new ways to incorporate smart sensors and other devices into their products. These sensors can monitor everything from temperature and humidity to air quality and energy usage, helping building owners and operators optimize their facilities for sustainability.

Another important trend in the future of precast detailing is the growing use of renewable materials. As the world seeks to reduce its reliance on fossil fuels and other non-renewable resources, precast detailing companies are exploring new materials that are more environmentally friendly. These materials can range from recycled concrete and steel to sustainably sourced timber and bamboo.

Finally, industry professionals will continue to play a critical role in the future of precast detailing and sustainability. Architects, engineers, contractors, and other professionals will need to collaborate closely to ensure that precast detailing is used in the most sustainable way possible. This will require ongoing education and training, as well as a commitment to using precast detailing in a way that maximizes its benefits for the environment.

Overall, the future of precast detailing and sustainability looks bright. As the construction industry continues to embrace sustainable building practices, precast detailing will remain an important tool for achieving those goals. With ongoing innovation, investment, and collaboration, precast detailing has the potential to help create a more sustainable, resilient, and equitable world for future generations.

Conclusion

In conclusion, precast detailing offers a range of benefits for sustainable building practices. From reducing material usage and waste to improving energy efficiency and durability, this approach has the potential to contribute to a more sustainable future. By embracing precast detailing, industry professionals can create a better, more sustainable world for future generations.